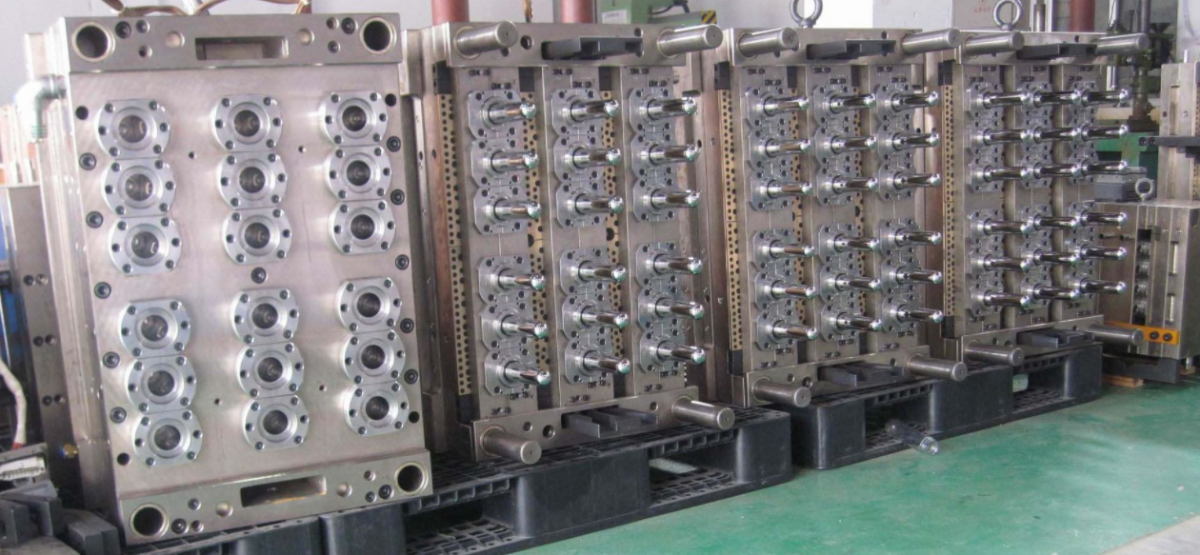

Customized PET Preforms Moulds, 8-96 Kab noj hniav

Peb muaj kev ntseeg siab pwm koom tes nrog kaum ob ntawm cov kws tshaj lij thiab cov cuab yeej ua haujlwm siab heev, xws li tsib axis CNC los ntawm DMG Lub Tebchaws Yelemees, FIDIA Ltalis.EDM los ntawm DAEHAN Kaus Lim Kauslim, CMM los ntawm Wenzel Lub Tebchaws Yelemees thiab COORD3 Ltalis.

Feem ntau PET preforms pwm yog ntau kab noj hniav, los ntawm 8 ob 96 kab noj hniav.Ntau cov pwm preform yog slender thiab ntws channel kev ua tau zoo ntawm PET tsis muaj zog, nws yog ib qho tseem ceeb uas yuav tau xaiv cov hlau tawv.

Peb lub template yog ua los ntawm stainless hlau los yog pre-hardened P20, thiab P20 template yog Nickelplated, nrog Rockwell hardness 38 ~ 40 degrees.

Cov cores, kab noj hniav thiab ntsia hlau qhov ncauj txais Sweden S136 los yog lub teb chaws Yelemees 2316, nrog Rockwell hardness 48 ~ 52 degrees.Txhua qhov kab noj hniav tau txais kev ywj pheej ntawm tus kheej-locking qauv.Qhov chaw ntawm txhua qhov kab noj hniav yog sib hloov, nrog cov qauv tsim nyog thiab kev saib xyuas yooj yim.

1: Kev tshaj lij kev paub hauv lub raj mis preform pwm kab noj hniav xws li 1 txog 96.

2: Adopts CAD software los tsim cov duab ntawm lub raj mis preform raws li, kom ntseeg tau qhov zoo ntawm lub raj mis molding.

3: Cov khoom siv xov ntawm lub raj mis preform pwm yog ua los ntawm cov khoom tuajNitrided steel, raws li thoob ntiaj teb cov qauv, nrog siab hardness.Txhua lub xov yog vented, nrog lub neej ntev kev pab cuam thiab tsis deformation.

4: Lub hauv paus ntawm lub raj mis preform pwm thiab kab noj hniav yog ua los ntawm corrosion-resistant steel,ruaj.

5: Lub raj mis preform pwm txais kev tsim qauv kub khiav, tso cai rau txhua qhov kab noj hniav kom nws tus kheej tswj qhov kub thiab txias, cua sov, thiab ua tiav qhov kub thiab txias.

6: Dawb txiavtxhaj qhov ncauj, txuag kev ua haujlwm thiab cov khoom siv raw.

7: Kub khiav nozzle yog tus kheej tswj rau qhov kub thiab txias.(Tshaj cov teeb meem ntawm kev ntxuav hniav dawb hauv qab thiab xaim kos duab thaum lub sijhawm tsim khoom).

8: Koob valve hom self-locking lub raj mis preform pwm: Txhua tus tub ntxhaisthiabkab noj hniavyogywj siabthiabmuab ob npaug rau nws tus kheej-locking, adjustable eccentricity, txo eccentricity, xyuas kom meej cov khoomsconcentricity thiab siab precision.Cov pwms ua haujlwmlub neej ntev.

9: Pwm tuaj yeem tsim raws liqauv thiab kos duab.Peb kuj muab PET preforms thiab cov khoom siv.

Qee qhov khoom siv rau kev siv, DuPont tshav kub rwb thaiv tsev txiv ntoo, HOSTET cua sov rings, Italia tooj liab nozzless, Japanese valve koob, tooj dag graphite phaj lubrication thiab hais txog.

1. Txais 45 #, S136, 2316 thiab lwm yam steels raws li cov neeg siv khoom xav tau.

2. Haum rau ntau hom thiab qauv ntawm lub raj mis tshuab tshuab.

3. 15000 RPM kev kub ceev engraving tshuab.

4. Daim iav polishing thiab cov dej txias txias zoo heev.

5. 8ml ~ 60L lub raj mis tshuab pwm muaj.