-

PET Induction Foil Liners

–Seal oils, medicines, foods, beverages, liquors, pesticides, agro-chemical, and cosmetics. –Waterproof, moistureproof, leakproof. –Anti-acid, anti-alkali, anti-corrosion. –Compliant with FAD food standard. –Customized printing is available. We have rich experience i...Read more -

EPTFE Plug For Agrichemical

The breathable plugs help packaging containers keep pressure balance between internal and external , prevent the container from expanding or collapsing, also prevent the liquid or powder inside the container leaking, improving the safety. The ePTFE waterproof and breathable film has three major f...Read more -

FDA Aluminium Foil Tablewares For Food

Taizhou Rimzer Rubber & Plastic Co., Ltd. is a leading manufacturer of high-quality aluminum foil tableware for food packaging and catering. With a focus on meeting the highest standards in food safety and convenience, we provide a wide range of aluminum foil products that are designed to mee...Read more -

Aluminum liquid cap.

Sterilization resistance and sealing testing are currently hot topics in the packaging industry. In the field of packaging of liquid products, aluminum liquid caps are favored for their excellent resistance to sterilization and excellent sealing performance. As an industry leader, Taizhou Rimzer ...Read more -

Customized PET Preforms Molds, 8-96 Cavities.

Known for its expertise in manufacturing custom PET preform molds from 8 to 96 cavities, Taizhou Ruimzer Rubber & Plastic Co., Ltd. has set the industry standard with its advanced technical capabilities and dedication to durability and precision. Our professional molds are equipped with hot r...Read more -

Soda Lime & Borosilicate Glass Cups.

Taizhou Ruize Rubber & Plastic Co., Ltd. specializes in the production of high-quality soda-lime glass and borosilicate glass products. Our glassware products are known for their smoothness, clarity, lightweight and durability. Additionally, we offer customizable options in size, color, and p...Read more -

Aluminium Beer Cans, FDA Food Standard.

Aluminum beer cans are an environmentally friendly and practical packaging container. As a leading manufacturer of beer cans, Taizhou Lize Rubber & Plastic Co., Ltd. is committed to providing customers with high-quality, environmentally friendly, and recyclable products. Our aluminum beer can...Read more -

Polyethylene foil gasket: achieving reliable container sealing and corrosion resistance.

As polyethylene containers are widely used in various industrial and commercial fields, the requirements for their sealing performance and anti-corrosion capabilities are increasing day by day. Taizhou Rimzer Rubber & Plastic Co., Ltd. leads the R&D and production of polyethylene foil sea...Read more -

What are the methods of PET bottle preform blow molding?

1. Extrusion blow molding Extrusion blow molding is one of the most widely used methods for plastic packaging containers. The powder (or granular material) of thermosetting plastic is melted through an extruder, and then made into a hot-melt tubular parison according to a special material tube. W...Read more -

Some knowledge about PET bottle preform injection molding.

PET bottle preforms are typical injection molding products, easy to transport, mostly made of plastic, with uniform texture and good insulation. They are an intermediate product for plastic bottles and oil barrels. Under a certain temperature and pressure, the mold is filled with raw materials, a...Read more -

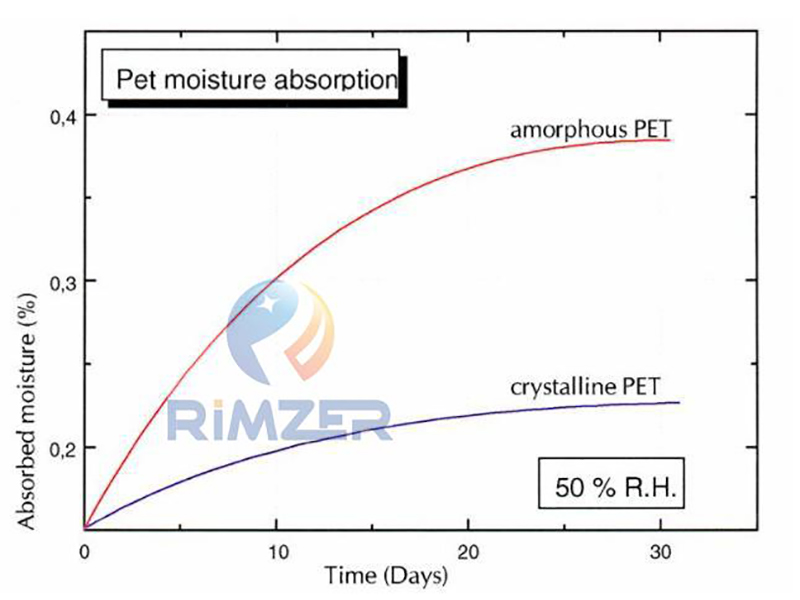

Why Taizhou Rimzer Dries PET Resin Before Producing Preforms?

In the process of producing PET preforms, drying PET raw materials is an essential link. In the production of PET preforms, PET raw materials are heated and pressurized, extruded by an extruder into plastic blanks, and then further processed into preforms. However, if th...Read more -

Why and How to Crystallize Bottleneck?

Crystallized bottleneck is mostly used for hot-filling to prevent bottle deformating, while the Non-crystallized bottleneck mostly for normal temperature or low-temperature filling. The crystal is whilte, helping bottleneck withstand the temperature as high as 100℃. To e...Read more