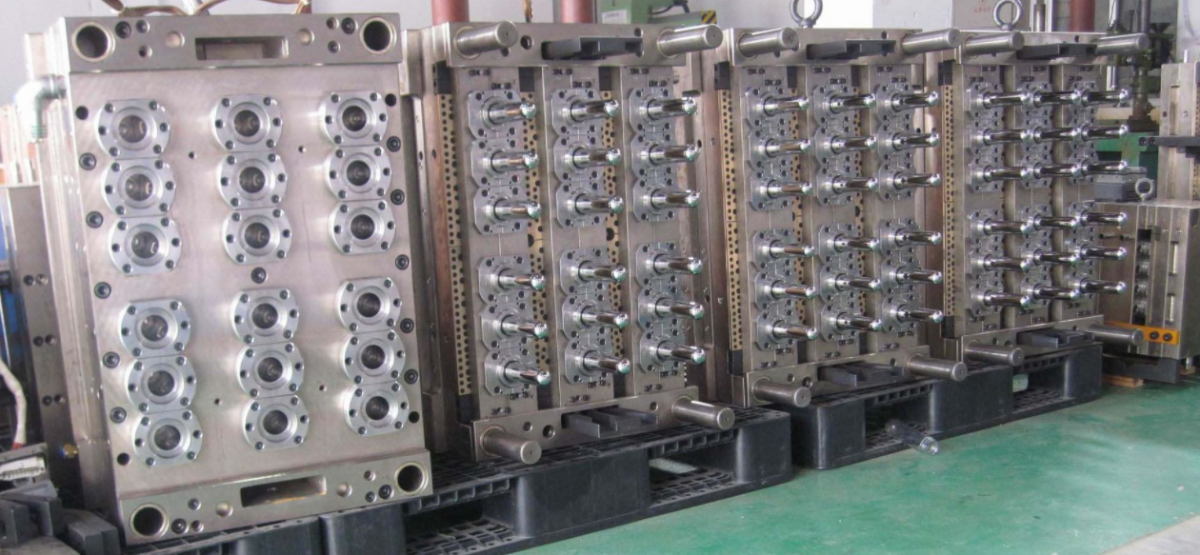

Customized PET Preforms Molds, 8-96 Cavities

We have reliable mold partners with dozen of professional technicians and advanced processing equipments, such as five axis CNC from DMG Germany, FIDIA Italy. EDM from DAEHAN Korea,CMM from Wenzel Germany and COORD3 Italy.

Most PET preforms molds are multi cavities, from 8 two 96 cavities. Many preform molds are slender and the flow channel performance of PET is weak, it is important to choose relatively hard steel.

Our template is made of stainless steel or pre-hardened P20, and P20 template is Nickelplated, with Rockwell hardness 38 ~ 40 degrees.

The cores, cavities and screw mouths adopt Sweden S136 or Germany 2316, with Rockwell hardness 48 ~ 52 degrees. Each cavity part adopts independent self-locking structure. The parts of each cavity are interchangeable, with reasonable structure and convenient maintenance.

1: Professional technical experience in bottle preform mold cavities ranging from 1 to 96.

2: Adopts CAD software to design the shape of the bottle preform based, ensuring the quality of bottle molding.

3: The thread material of the bottle preform mold is made of imported Nitrided steel, according to international standards, with high hardness. Each thread is vented, with long service life and no deformation.

4: The core of the bottle preform mold and the cavity are made of corrosion-resistant steel, durable.

5: The bottle preform mold adopts advanced hot runner design, allowing each cavity to independently control temperature, heat, and achieve uniform temperature.

6: Free cutting injecting mouth, saving labor and raw materials.

7: The hot runner nozzle is individually controlled for temperature. (Solve the problems of bottom whitening and wire drawing during the production process).

8: Needle valve type self-locking bottle preform mold: Each core and cavity are independent and double self-locking, adjustable eccentricity, reducing eccentricity, ensuring products concentricity and high precision. The molds work long life.

9: Molds can be designed according to sample and drawing. We also supply PET preforms and material.

Some spare parts for reference, DuPont heat insulation nut, HOSTET heating rings, Italia copper nozzless, Japanese valve needles, brass graphite plate lubrication and so on.

1.Adopt 45#, S136, 2316 and other steels according to customers’ requirements.

2. Adapt to various brands and models of bottle blowing machines.

3. 15000 RPM high speed engraving machine.

4. Surface mirror polishing and excellent cooling water channels.

5. 8ml ~ 60L bottle blowing molds are available.